MANUFACTURING

pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india pharmaceutical industry in india

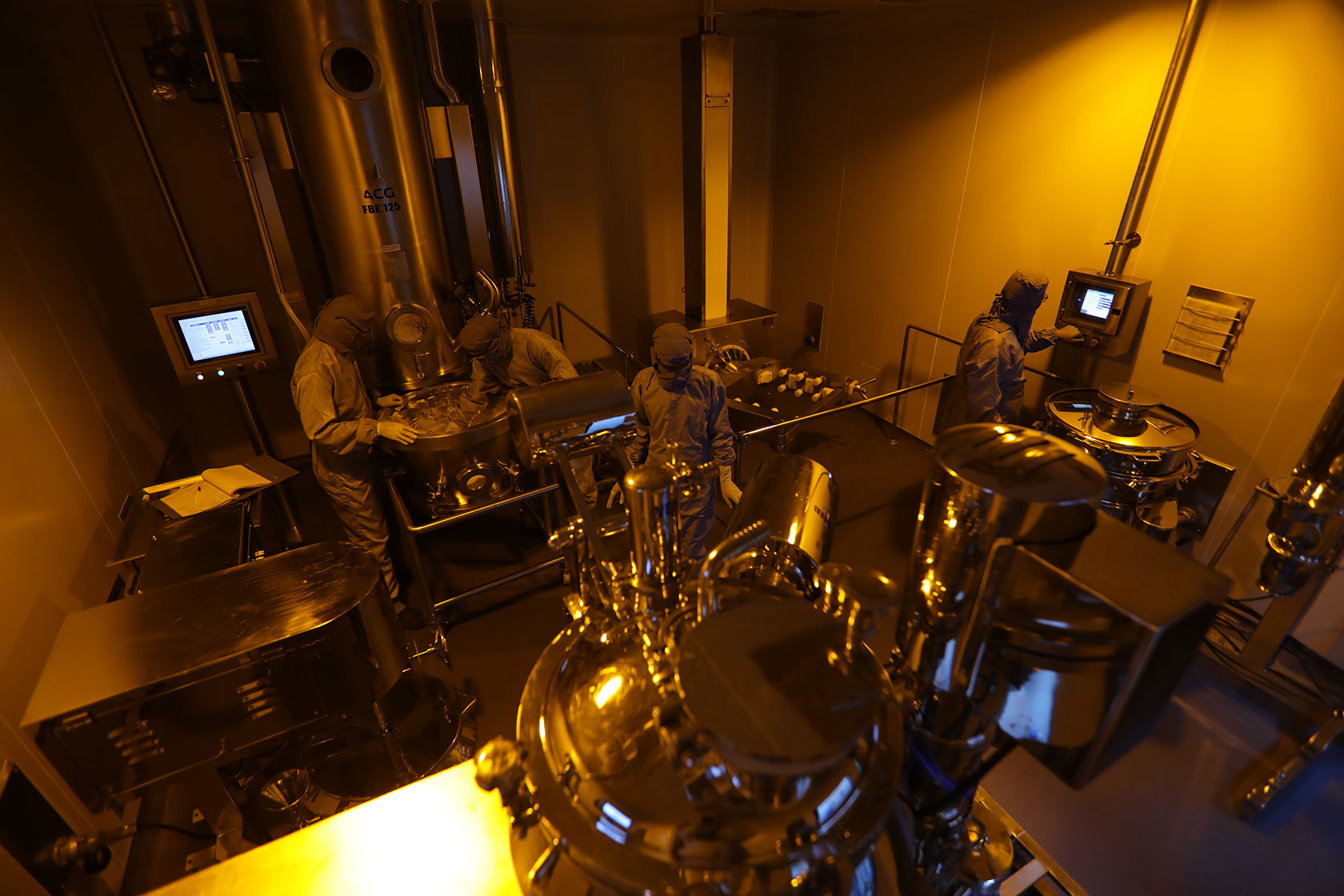

Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area. Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes. CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.

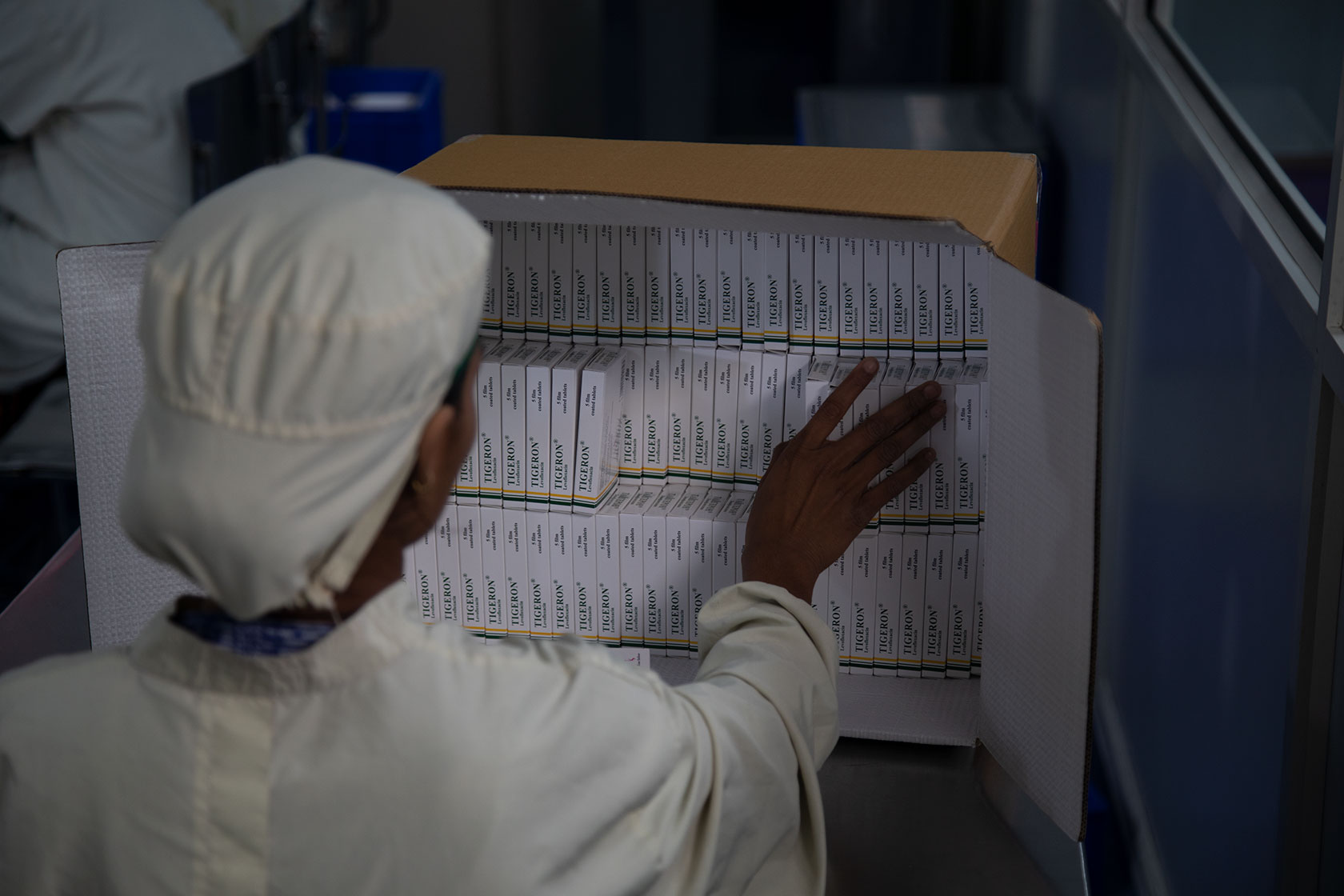

Kusum’s world-class pharmaceutical manufacturing plants at Bhiwadi, Rajasthan and Pithampur, Indore consists of units and systems that are designed to meet all international norms. ISO 9001 and ISO 14001 certified pharmaceutical plants manufacture oral solids and topical dosage forms such as tablets, pellets, topical liquids, creams, ointments, shampoo and wax-based suppositories and pessaries. Pharmaceutical packaging facilities are available in blisters, cold forming blisters, sachets, bottles, and tubes.

CGMP & Good Documentation practices resulted in the consistent quality of pharmaceutical products. All core drug manufacturing areas have dedicated heating, ventilating, and air-conditioning (HVAC) systems with 15 Air Handling Units (AHUs) and High-Efficiency Particulate Air (HEPA) filters to ensure air purity within the production area.

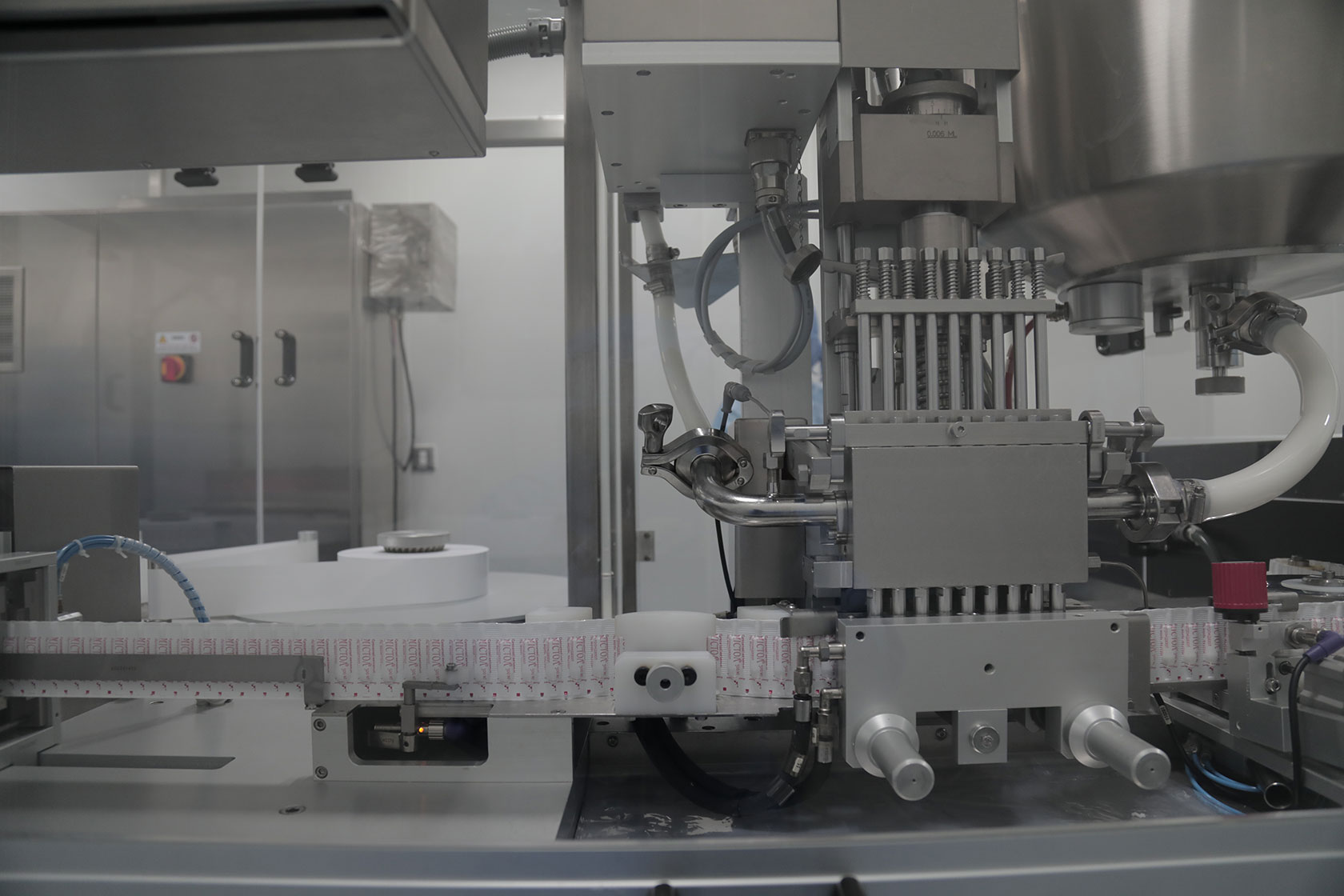

The manufacturing area for quality pharmaceutical products is equipped with PLC-based equipment, which meets CGMP standards. Right from raw material inputs, packaging material and in-process checks, strict guidelines are institutionalized to prevent any contamination.

Access to the pharmaceutical production area is restricted, and utmost care is taken to keep the area germ-free. Our obligation to manufacture quality pharmaceutical products ensures that there are no shortcuts.

Automated electronic weight-based filter processes are in place, which ensures the rejection of faultily packed medicines. All packaging materials for pharmaceutical products carry proper description and regulatory communication in the local language of countries where it is sold.

Our Capabilities

Kusum, a fully integrated young pharmaceutical group in India and catering to 27 export markets is focused on delivering high-quality and efficient therapeutic pharmaceutical solutions to healthcare professionals and patients with varied medical needs.

All the resources and expertise in Kusum is focused to develop, manufacture, register and market pharmaceutical products in over 27 countries globally. It includes in-house pharmaceutical R&D, Regulatory Affairs, Drug Quality Assurance, Warehousing, Pharmaceutical Marketing & Sales, and all financial activities under one roof – or Kusum’s core capacity to improve the quality of life.

Kusum is Committed to Quality

At Kusum, our commitment to pharmaceutical quality and compliance is above everything else. We take great pride in our processes of pharmaceutical manufacturing ensure the highest quality and efficacy standards in every product we deliver.

We follow a robust quality control program to ensure that all our products meet and exceed good manufacturing practices and our customers receive the highest quality pharmaceutical product every time.

Extensive Quality Assurance and Compliance Program: –

- Extensive standard operating and cleaning procedures

- Dedicated preventative maintenance and calibration personnel

- Qualification and validation system

- Ongoing internal and external training

- Regular internal and external audit program

- Detailed documentation practices

- Regulatory Affairs Expertise

The Regulatory Affairs departments at Kusum Healthcare ensure that the company complies with all the regulations and laws concerning the pharmaceutical business. It is an important part of the organizational structure in Kusum Healthcare. Internally it liaises at the interface of drug development, manufacturing, marketing, and clinical research. Externally it is the key interface between the company and the regulatory authorities of respective countries wherever the company conducts its business activities.

Gallery